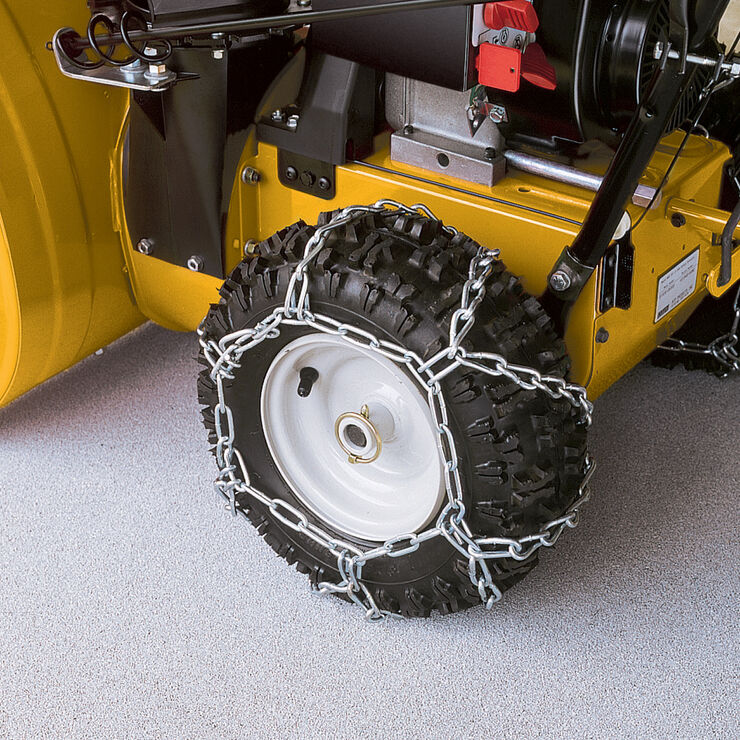

So you’ve got yourself a trusty snowblower, ready to tackle the winter storms that will inevitably come knocking at your door. But before you hit the icy terrain, there’s one essential accessory you need to consider – tire chains. These seemingly simple chains play a vital role in ensuring your snowblower maintains traction on slippery surfaces, preventing it from skidding or getting stuck in the snow. But with so many options available, how do you know which tire chains are right for your snowblower? In this article, we’ll break it down for you, providing you with all the information you need to make an informed decision and keep your snowblower running smoothly throughout the winter season.

This image is property of www.troybilt.com.

Understanding Tire Chains

What are tire chains?

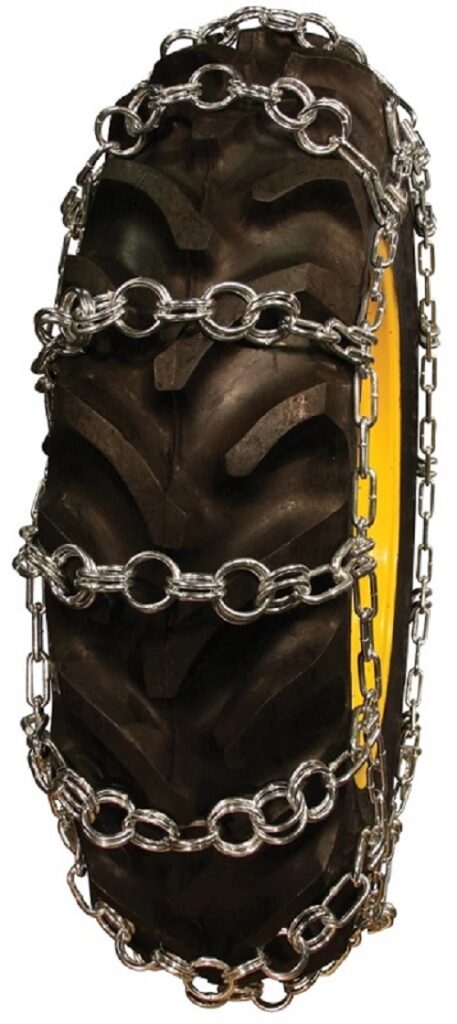

Tire chains are devices made of metal or synthetic materials that are designed to provide added traction to your snowblower’s tires when operating in snowy or icy conditions. These chains consist of interconnected links that wrap around the tires and help improve grip, allowing the snowblower to maneuver more easily and effectively through snow-covered surfaces.

Why are tire chains important for a snowblower?

Snowblowers are powerful machines that help clear snow effectively. However, they can face challenges when operating on slippery surfaces. This is where tire chains come into play. By installing tire chains, you enhance the traction and grip of your snowblower, making it easier to navigate through snow and ice. Tire chains improve the overall performance and efficiency of your snowblower, allowing it to effectively clear snow and keep your pathways safe and accessible.

Types of tire chains

There are various types of tire chains available in the market, each offering its own unique characteristics and benefits. Here are some common types:

-

Steel chains: Steel chains are the most durable option and work well in extreme winter conditions. They provide excellent traction but can be noisy and may cause damage to delicate surfaces like asphalt.

-

Zinc-plated chains: These chains are coated with zinc, which helps prevent rust and corrosion. They offer good traction and are less likely to damage surfaces, making them suitable for both residential and commercial use.

-

Composite chains: Composite chains are made of a blend of materials, such as rubber and metal, to provide a balance between durability and surface protection. They are relatively quiet, lightweight, and offer moderate traction.

Choosing the right type of tire chains depends on your specific needs, budget, and the terrain you’ll be operating in. Considering factors like durability, traction, and surface protection will help you make an informed decision.

Consider Your Snowblower Size and Model

Determining the size and model of your snowblower

To select the appropriate tire chains for your snowblower, you need to determine its size and model. Snowblower sizes vary, ranging from compact models to larger commercial-grade ones. Start by checking your snowblower’s user manual or measuring the width and diameter of the tires to accurately determine the size.

Additionally, note down the model number and brand of your snowblower. This information will help you find compatible tire chains, as manufacturers often provide guidelines and recommendations regarding compatible tire chains for their specific models.

Finding compatible tire chains

Once you have the size and model information, you can look for tire chains that are compatible with your snowblower. Many tire chain manufacturers provide compatibility charts or online tools that match tire chain options to different snowblower models. Consult these resources or reach out to the manufacturer’s customer support for assistance in finding the right tire chains for your specific snowblower.

Remember, using tire chains that are specifically made for your snowblower’s size and model ensures proper fit and optimal performance.

This image is property of www.cubcadet.com.

Assess Your Snowblowing Needs

Identifying your typical snowblowing conditions

Every snowblower user faces unique snowblowing conditions. Consider the average snowfall in your area, the frequency of use, and the type of terrain you’ll be operating on. If you live in an area with heavy snowfall or encounter deep snow regularly, you’ll require tire chains with superior traction and durability.

On the other hand, if you typically deal with lighter snowfall or have mostly flat terrain, you might not need heavy-duty chains. Understanding your typical snowblowing conditions helps narrow down the type of tire chains that will best suit your needs.

Considering the terrain and incline

The terrain on which you’ll be using your snowblower plays a significant role in determining the type of tire chains you should choose. If you have a flat driveway or pathway, standard chains with moderate traction may be sufficient. However, if you have a sloped driveway or frequently encounter steep inclines, you’ll need tire chains with excellent grip to ensure safe and efficient snowblowing.

Consider the inclination and roughness of the terrain you’ll be operating on to make an informed decision regarding the level of traction required for your tire chains.

Choosing the Right Chain Material

Steel chains

Steel chains are the most common and popular choice due to their durability and reliability. They can withstand harsh winter conditions, including ice and packed snow. Steel chains provide excellent traction, ideal for heavy-duty snowblowing tasks. However, keep in mind that steel chains can be noisy and may cause damage to delicate surfaces like asphalt. They are best suited for rough terrains and commercial use.

Zinc-plated chains

Zinc-plated chains are steel chains coated with zinc to prevent rust and corrosion. These chains offer good traction and perform well in moderate winter conditions. They are less likely to damage surfaces, making them suitable for residential use. Zinc-plated chains strike a balance between durability, surface protection, and affordability.

Composite chains

Composite chains are a newer type of tire chain, combining materials such as rubber and metal. These chains offer moderate traction, making them suitable for lighter snowblowing tasks and less rugged terrains. They are lightweight, relatively quiet, and provide better surface protection compared to steel chains. Composite chains are a good option for residential use, where noise and surface damage are concerns.

Consider your specific snowblowing needs, the terrain you’ll be operating on, and the level of traction required when choosing the right chain material for your snowblower.

This image is property of kenjones.com.

Understanding Chain Traction

The importance of traction

Traction is crucial when operating a snowblower, especially in challenging winter conditions. Tire chains enhance traction by providing additional grip on slippery surfaces. With improved traction, your snowblower can effectively propel forward, maneuver easily, and clear snow more efficiently.

When choosing tire chains, consider the type of chain tread pattern on the link surface. The design of the chains affects the level of traction they provide. Different chain tread patterns are suitable for different snowblowing conditions, terrains, and inclines.

Exploring different chain tread patterns

There are several common chain tread patterns available, each designed to optimize traction in specific conditions:

-

V-Bar chains: These chains have metal bars shaped like a “V” that bite into ice and hard-packed snow. V-Bar chains provide exceptional traction, making them ideal for icy surfaces or areas with severe winter conditions.

-

Ladder chains: Ladder chains have horizontal bars that run across the tire. They offer good traction on snowy and icy surfaces, making them a versatile option for various snowblowing conditions.

-

Diamond chains: Diamond chains have diamond-shaped metal studs placed diagonally across the chain surface. They provide stable traction and are suitable for both packed snow and icy surfaces.

Consider the typical snow conditions you encounter and the level of traction required when selecting the chain tread pattern that best suits your snowblower’s needs.

Evaluating Chain Durability

Durability considerations

Durability is an essential factor to consider when choosing tire chains. You want chains that can withstand tough winter conditions and remain effective for multiple seasons. The durability of tire chains depends on various factors, including the materials used and the manufacturing quality.

Steel chains are known for their exceptional durability, making them a reliable option for heavy-duty snowblowing tasks. Zinc-plated chains offer corrosion resistance and a decent lifespan. Composite chains provide durability with added flexibility and surface protection.

Evaluate your snowblowing needs, expected frequency of use, and the harshness of your winter conditions to determine the level of durability required for your tire chains.

Understanding the lifespan of different tire chains

The lifespan of tire chains can vary depending on factors such as usage, terrain, and maintenance. Steel chains generally have a longer lifespan compared to zinc-plated and composite chains. Proper care, such as regular cleaning and lubrication, can help extend the lifespan of tire chains.

Consider the estimated lifespan of different tire chains when making your selection. Investing in durable and long-lasting chains ensures reliable performance and value for your snowblowing needs.

This image is property of www.tirechainsrus.com.

Examining Ease of Installation

How easy is it to install the tire chains?

When shopping for tire chains, consider how easy they are to install on your snowblower’s tires. Some chains require specific tools or complicated installation steps, while others have user-friendly designs that simplify the installation process.

Look for tire chains that come with clear instructions and require minimal effort to install. Quick and hassle-free installation saves you time and frustration when preparing your snowblower for winter use.

Considering self-tensioning options

Self-tensioning tire chains are designed to automatically adjust and maintain proper tension throughout use. These chains utilize tensioning devices or springs, reducing the need for manual readjustment and ensuring optimal performance.

Consider opting for self-tensioning tire chains if ease of use and convenience are important to you. They eliminate the hassle of constant tension adjustments and ensure a secure fit on your snowblower’s tires.

Considering Budget and Value

Determining your budget

Budget is an important consideration when choosing tire chains for your snowblower. Tire chain prices vary depending on factors such as the chain material, durability, and brand reputation. Determine how much you are willing to spend on tire chains and look for options that fall within your budget.

While it may be tempting to opt for the cheapest tire chains available, keep in mind that quality and performance can vary significantly. Striking a balance between affordability and quality is crucial to ensure long-term value for your investment.

Balancing quality and price

When evaluating tire chain options, consider the overall quality and value they offer. Look for reputable brands and read customer reviews to gain insights into the performance and durability of different tire chains. Remember that higher-quality chains may come with a higher price tag, but they often offer better traction, durability, and longevity.

Choose tire chains that provide the best value for your budget, considering factors such as durability, traction, ease of installation, and overall customer satisfaction.

This image is property of www.etrailer.com.

Reading Customer Reviews and Recommendations

Importance of customer reviews

Customer reviews are an excellent resource when choosing the right tire chains for your snowblower. Reading reviews from other snowblower owners who have used the chains provides valuable insights into their performance, durability, and overall satisfaction. Look for reviews that specifically mention snowblower use to ensure relevance to your needs.

Pay attention to common themes in the reviews, such as the reliability of the chains, ease of installation, and performance in various snow conditions. Real-life experiences from other customers can help you make an informed decision and avoid potential pitfalls.

Getting recommendations

In addition to reading customer reviews, consider seeking recommendations from friends, family, or neighbors who own snowblowers. Personal recommendations can provide firsthand information on the performance, durability, and suitability of specific tire chains.

Snowblower owners who have experience using tire chains may offer valuable tips and insights, helping you choose the right chains for your snowblower with greater confidence.

Consulting With Experts and Retailers

Seeking advice from experts

If you are still unsure about which tire chains to choose for your snowblower, consider seeking advice from experts in the field. Snowblower manufacturers, mechanics, and professionals at local hardware stores or equipment rental centers can provide valuable guidance based on their expertise and experience.

These experts can recommend tire chain options based on your snowblower model, typical snowblowing conditions, and specific requirements. They can answer your questions and provide additional insights to ensure you make an informed decision.

Talking to snowblower retailers

When purchasing tire chains, consider visiting snowblower retailers or contacting them online. The staff at these retailers have knowledge about different tire chain options and can help you identify the best fit for your snowblower. They often have access to compatibility charts, manufacturer guidelines, and firsthand experience with various tire chains.

Discuss your snowblowing needs and concerns with the retailer’s staff to receive personalized recommendations and ensure you choose the right tire chains for your specific snowblower model and conditions.

Choosing the right tire chains for your snowblower involves considering factors such as size, model, terrain, traction, durability, ease of installation, budget, and customer reviews. By carefully evaluating these aspects and consulting with experts and retailers, you can select tire chains that enhance the performance of your snowblower, improve safety, and make snowblowing a more efficient and enjoyable task.