So, you’ve got yourself a snowblower and you’re ready to take on the snow-covered winter wonderland. But wait, have you ever wondered how to check and refill the transmission fluid in your trusty machine? Well, you’re in luck because in this article, we’re going to walk you through the step-by-step process of checking and topping up the transmission fluid in your snowblower. Whether you’re a seasoned snowblower owner or a newbie, we’ve got you covered.

Checking the Transmission Fluid Level

Locating the transmission fluid dipstick

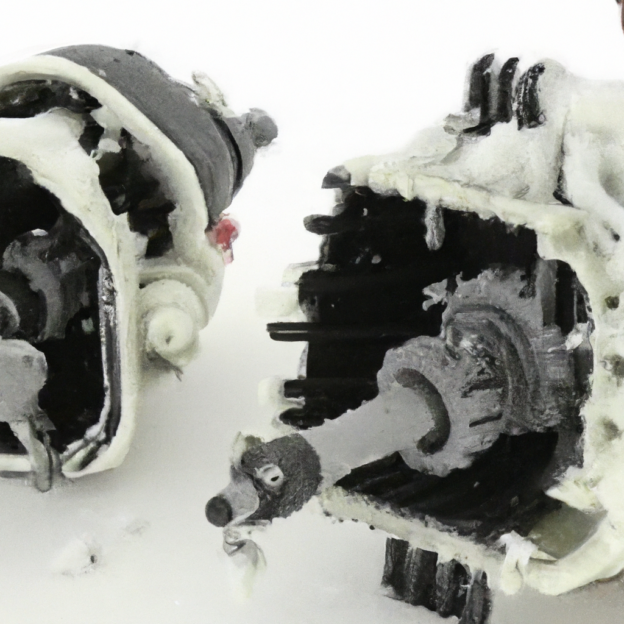

To check and refill the transmission fluid in your snowblower, you’ll need to follow a few simple steps. The first step is to locate the transmission fluid dipstick. This is usually located near the engine, often at the back or side of the machine. Look for a long, slender metal or plastic rod with a ring or handle on top. The dipstick is used to measure the fluid level in the transmission, so it’s an essential tool in this process.

Warming up the snowblower engine

Before you can accurately check the transmission fluid level, it’s important to first warm up the snowblower engine. Start by making sure the snowblower is in a well-ventilated area, as you’ll need to let the engine run for a few minutes. Once you’ve ensured proper ventilation, start the engine and let it idle for about five to ten minutes. This will allow the transmission fluid to reach its optimal operating temperature, ensuring an accurate reading when you check the fluid level.

Removing the dipstick and inspecting the fluid level

Once the engine has warmed up, it’s time to check the transmission fluid level. To do this, locate the dipstick and pull it out of the dipstick tube. Wipe off any fluid on the dipstick with a clean cloth or paper towel, and then reinsert it fully into the tube. Be sure to remove the dipstick again, and this time take note of the fluid level. On the dipstick, you’ll find markings indicating the acceptable range for the transmission fluid level. The fluid should ideally fall within this range. If the fluid level is below the minimum mark, you’ll need to add more transmission fluid.

Adding transmission fluid if necessary

If you find that the transmission fluid level is below the minimum mark on the dipstick, it’s crucial to add more fluid to avoid damaging the snowblower’s transmission. To add transmission fluid, you’ll need to locate the fill hole. This is usually located on the side or back of the snowblower, near the area where the dipstick is located. It may have a fill plug or cap that needs to be removed. Once you’ve located the fill hole, use a funnel to pour the appropriate amount of transmission fluid into the hole. Be sure to check the snowblower’s manual for the correct type and quantity of transmission fluid to use. Once you’ve added the necessary fluid, reinsert the dipstick and check the fluid level again to ensure it falls within the acceptable range.

Refilling the Transmission Fluid

Gathering the necessary tools and materials

Before you begin refilling the transmission fluid in your snowblower, it’s important to gather all the necessary tools and materials. You’ll need a funnel that fits securely into the fill hole, a clean cloth or paper towel to wipe any spills, and most importantly, the correct type and quantity of transmission fluid as specified in your snowblower’s manual. It’s essential to use the recommended type of fluid to ensure optimal performance and prevent damage to the transmission.

Locating the transmission fluid fill plug or cap

To refill the transmission fluid, you’ll first need to locate the fill plug or cap. This is where you’ll pour the transmission fluid into the snowblower. The fill plug or cap is typically located near the dipstick and may be labeled or color-coded for easy identification. It may require the use of a tool, such as a wrench or socket, to remove it. Refer to your snowblower’s manual for the exact location and instructions on how to remove the fill plug or cap.

Preparing the snowblower for refill

Once you’ve located the fill plug or cap, it’s important to prepare the snowblower for the refill process. Start by ensuring the snowblower is on a level surface and turned off. This will prevent any accidents or spills during the refilling process. Additionally, take the time to clean around the fill hole to remove any debris or dirt that may fall into the transmission. Keeping the area clean will help maintain the integrity of the transmission fluid and prevent any potential damage to the snowblower.

Pouring transmission fluid into the fill hole

With the snowblower prepared and the fill plug or cap removed, it’s time to refill the transmission fluid. Insert the funnel securely into the fill hole to prevent any spills or fluid loss. Slowly pour the transmission fluid into the funnel, allowing it to flow into the transmission. Take care not to overfill the transmission, as this can lead to issues with performance and potential damage. Use the dipstick to check the fluid level periodically as you pour, ensuring that it falls within the acceptable range indicated on the dipstick. Once you’ve added the correct amount of fluid, remove the funnel and securely tighten the fill plug or cap.

Ensuring Proper Transmission Fluid

Choosing the correct type of transmission fluid

When checking and refilling the transmission fluid in your snowblower, it’s crucial to select the correct type of fluid. Different snowblower models may require specific types of transmission fluid, so it’s essential to consult your snowblower’s manual or contact the manufacturer to determine the appropriate fluid to use. Using the wrong type of fluid can lead to poor performance, potential damage to the snowblower, and even void warranties.

Consulting the snowblower’s manual for specifications

To ensure proper transmission fluid levels and avoid any potential issues, it’s important to consult your snowblower’s manual for specifications. The manual will provide detailed information on the type of fluid recommended by the manufacturer, the desired fluid capacity, and any specific instructions for checking and refilling the transmission fluid. Following the manual’s guidelines will help ensure the longevity and optimal performance of your snowblower.

Checking the fluid capacity and level requirements

In addition to using the correct type of transmission fluid, it’s important to be aware of the snowblower’s fluid capacity and level requirements. The manual will specify the amount of fluid needed to achieve the proper level. It’s crucial not to overfill or underfill the transmission, as both can result in performance issues. By checking and maintaining the correct fluid level, you’ll help prevent unnecessary wear and tear on the transmission and ensure smooth operation of your snowblower.

In conclusion, checking and refilling the transmission fluid in your snowblower is a simple yet vital maintenance task. By following the outlined steps and guidelines, you can ensure the proper functioning and longevity of your snowblower’s transmission. Remember to consult your snowblower’s manual, gather the necessary tools and materials, and perform the checks and refills in a safe and responsible manner. Regularly checking and maintaining the transmission fluid level will help keep your snowblower running smoothly and efficiently, allowing you to tackle those winter snowfalls with ease.