Hey everyone! Today we want to talk about something that might seem a little bit strange, but bear with us. Have you ever wondered if you should dry off your snow blower after each use? We know it might seem like a small detail, but trust us, it can make a big difference in the long run.

In our upcoming article, we’ll dive into the reasons why drying off your snow blower after each use is actually a good idea. We’ll explain how moisture accumulation can lead to rust and damage, and we’ll share some easy tips on how to properly dry off your snow blower to prolong its lifespan. So if you’re interested in learning more about this topic, stay tuned for our in-depth article on the importance of drying off your snow blower after each use.

This image is property of mobileimages.lowes.com.

Why drying off your snow blower is important

Prevents rust and corrosion

During the winter months, your snow blower is exposed to moisture from the snow and ice it clears. If left wet, this moisture can lead to rust and corrosion on the metal parts of your snow blower. Rust can weaken the components and cause them to break down over time, reducing the overall lifespan of your machine.

By taking the time to dry off your snow blower after each use, you can prevent rust from forming and keep your machine in optimal condition.

Extends the lifespan of your snow blower

Snow blowers are an investment, and it’s important to protect that investment by ensuring its longevity. By properly drying off your snow blower, you can prevent damage caused by rust and corrosion, which can significantly extend the lifespan of your machine. A well-maintained snow blower can last for many years, providing you with reliable performance season after season.

Ensures proper functioning in future uses

When moisture is left on your snow blower, it can freeze and cause blockages in the chute, auger, and other moving parts. This can result in your snow blower not functioning properly or even becoming completely clogged, rendering it useless until the blockage is removed.

By drying off your snow blower after each use, you can prevent these blockages from occurring and ensure that your machine is ready to perform at its best in future uses.

Steps to dry off your snow blower after each use

Turn off the engine

Before you begin drying off your snow blower, make sure to turn off the engine and remove the key. This eliminates any risk of accidental startup while you are working on the machine.

Remove any remaining snow or ice

Using a brush or your gloved hand, remove any remaining snow or ice from the surface of your snow blower. Pay close attention to the chute, auger, and other areas where snow tends to accumulate. Clearing off the snow and ice ensures that there is no excess moisture left on the machine.

Wipe down the exterior

Using a clean, dry cloth, thoroughly wipe down the exterior of your snow blower. This includes the handlebars, control panel, and any other accessible surfaces. Wiping off the moisture helps to prevent rust and corrosion from forming and keeps your machine looking clean and well-maintained.

Clean the auger and chute

To ensure proper functioning, it’s important to clean the auger and chute of your snow blower. Remove any snow or debris that may be stuck in these areas. Use a brush or your gloved hand to carefully remove any blockages. This step is crucial for preventing clogging and blockages in future uses.

Inspect and remove any debris

Take the time to inspect your snow blower for any debris that may have built up during use. Check the wheels, belts, and other components for any stuck or trapped debris that could potentially cause problems. Remove any debris that you find to ensure optimal performance.

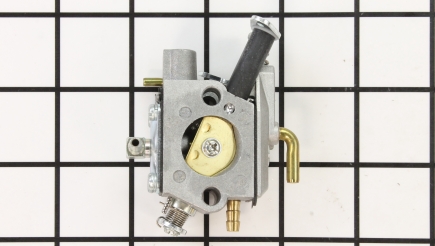

Check and clean the carburetor

The carburetor is an important component of your snow blower, as it regulates the fuel mixture. It’s essential to keep this part clean and free of debris. Consult your snow blower’s manual for specific instructions on how to clean and maintain the carburetor. This step will ensure that your snow blower continues to run smoothly.

Drain the fuel tank

If you don’t plan on using your snow blower for an extended period of time, it’s recommended to drain the fuel tank. Storing your snow blower with fuel in the tank can lead to fuel degradation and potentially damage the engine. Follow the manufacturer’s guidelines for properly draining the fuel tank to prevent any issues.

Store in a dry and protected area

Once you have finished drying off your snow blower, it’s important to store it in a dry and protected area. Moisture and extreme temperatures can damage the machine during storage, so choose a location that is free from moisture and temperature fluctuations. A garage or shed with proper ventilation is ideal.

Benefits of drying off your snow blower

Prevents clogging and blockages

By drying off your snow blower after each use, you can prevent the accumulation of moisture, which can freeze and cause blockages in the chute, auger, and other moving parts. This ensures that your snow blower will be ready to perform when you need it, without any unexpected clogging issues.

Reduces the chances of malfunctioning

A wet snow blower is more prone to malfunctioning due to rust, corrosion, and freezing. By properly drying off your machine, you can significantly reduce the chances of malfunctioning and ensure that your snow blower functions properly whenever you need it.

Saves time and effort in future uses

Properly drying off your snow blower after each use can save you time and effort in the long run. By preventing blockages and malfunctioning, you won’t have to spend extra time troubleshooting or repairing your machine. A well-maintained snow blower will be ready to clear snow efficiently and effectively without any unexpected issues.

Common misconceptions about drying off snow blowers

It’s not necessary if the snow blower is made of stainless steel

While stainless steel is more resistant to rust and corrosion, it is not completely impervious. Moisture can still cause damage to stainless steel parts over time. Drying off your snow blower after each use is necessary regardless of its material composition.

Drying off can cause damage to certain parts

When done correctly, drying off your snow blower will not cause any damage to its parts. It’s important to use a dry cloth or brush and avoid using excessive force that may lead to scratches or other cosmetic damages. Take care when wiping down sensitive areas, such as the control panel or engine.

Only necessary in extreme weather conditions

Drying off your snow blower after each use is necessary regardless of the weather conditions. Moisture can accumulate even in mild conditions, and taking the time to dry off your machine will help prevent rust, corrosion, and other issues in the long run.

This image is property of www.weingartz.com.

Effects of not drying off your snow blower

Rust and corrosion

Moisture left on a snow blower can lead to rust and corrosion on metal parts. Rust weakens the components and can cause them to break down over time, reducing the overall performance and lifespan of the machine.

Reduced performance and efficiency

A wet or clogged snow blower will not perform optimally. Moisture can freeze and cause blockages in the chute and auger, resulting in reduced performance and efficiency. Your machine may struggle to clear snow effectively or not function at all.

Frequent breakdowns and repairs

Neglecting to dry off your snow blower can lead to frequent breakdowns and the need for repairs. Rust, corrosion, and blockages can cause various components to malfunction or break down entirely. This can result in costly repairs and a snow blower that is unreliable.

Expert recommendations for drying off snow blowers

Manufacturers’ guidelines

Always refer to the manufacturer’s guidelines for your specific snow blower model. These guidelines will provide instructions on how to properly dry off your machine and any additional maintenance steps you should follow.

Winter maintenance Tips

In addition to drying off your snow blower, there are other winter maintenance tasks that should be performed regularly to ensure optimal performance. These tasks may include checking and replacing belts, lubricating moving parts, and inspecting the overall condition of your machine. Following winter maintenance tips can help prolong the lifespan of your snow blower.

Importance of regular cleaning and drying

Regular cleaning and drying of your snow blower are essential for its longevity and consistent performance. By incorporating these tasks into your snow-clearing routine, you can prevent rust, corrosion, and other issues that can arise from neglecting proper maintenance.

This image is property of contentgrid.homedepot-static.com.

Alternative options for snow blower protection

Using a snow blower cover

A snow blower cover can provide an extra layer of protection when storing your machine. It can help keep moisture, dust, and debris away from the snow blower, reducing the chances of rust and corrosion forming. Ensure that the cover fits properly and is made of a waterproof and breathable material.

Applying rust-resistant coatings

For added protection against rust and corrosion, you can apply rust-resistant coatings to the metal parts of your snow blower. These coatings create a barrier between the metal and moisture, preventing damage. Consult your snow blower’s manual or a professional for recommendations on suitable rust-resistant coatings.

Storing in a climate-controlled area

If possible, store your snow blower in a climate-controlled area. Extreme temperatures and fluctuations in humidity can cause damage to your machine. Storing it in a controlled environment can help maintain its performance and prevent issues caused by environmental factors.

The role of proper storage in snow blower maintenance

Choosing the right storage area

When it comes to storing your snow blower, choose an area that is dry, well-ventilated, and protected from the elements. A garage or shed with proper insulation is ideal. Avoid storing your snow blower directly on the ground to prevent moisture from seeping in.

Avoiding exposure to moisture and extreme temperatures

Moisture and extreme temperatures can cause damage to your snow blower during storage. Be mindful of where you place your machine and ensure that it is protected from any potential sources of moisture, such as leaks or condensation. Extreme temperatures can lead to freezing or other issues, so it’s important to store your snow blower in a controlled environment.

Proper placement and positioning

When storing your snow blower, make sure it is placed on a level surface and in a position that prevents any components from being strained or damaged. Follow the manufacturer’s guidelines for proper placement and positioning to ensure that your machine stays in optimal condition during storage.

This image is property of contentgrid.homedepot-static.com.

Additional tips and considerations

Regular maintenance schedule

In addition to drying off your snow blower after each use, it’s important to follow a regular maintenance schedule. This may include oil changes, spark plug replacements, and other maintenance tasks outlined in your snow blower’s manual. Regular maintenance will help keep your machine in top shape and prevent any unexpected issues.

Inspection of belts and blades

Regularly inspect the belts and blades of your snow blower for any signs of wear or damage. Replace any worn or damaged belts and sharpen or replace blades as necessary. Properly functioning belts and blades are essential for optimal performance.

Importance of proper fuel storage

When storing your snow blower for an extended period of time, it’s important to properly store the fuel. Use fuel stabilizers to prevent degradation and minimize the risks of fuel-related issues. Follow the manufacturer’s guidelines for fuel storage and consult a professional if you have any questions or concerns.

Conclusion

Drying off your snow blower after each use is crucial for its longevity and performance. By taking the time to properly dry off your machine, you can prevent rust, corrosion, and other issues that can arise from moisture exposure. Additionally, regular maintenance and proper storage will further ensure optimal performance and extend the lifespan of your snow blower.

Remember to follow the manufacturer’s guidelines, consider alternative options such as covers or rust-resistant coatings, and conduct regular inspections and maintenance tasks. By including drying off your snow blower in your snow-clearing routine, you can enjoy the benefits of a well-maintained machine and efficient snow clearing for years to come.

This image is property of contentgrid.homedepot-static.com.