In this article, we will explore the different snowblower brands available on the market and discuss their features and performance. We will compare popular brands such as Toro, Craftsman, and Honda, and provide you with valuable insights to help you make an informed decision. By the end, you will have a better understanding of the best brand of snowblower to buy based on your specific needs and budget. So, let’s dive in and find the perfect snowblower for you! When it comes to choosing a snowblower, there are several factors to consider. From power source and clearing width to performance and durability, each aspect plays a crucial role in determining the best brand of snowblower to buy. In this article, we will explore these factors in detail, review some of the top snowblower brands in the market, and provide a comprehensive comparison of popular snowblower models.

This image is property of cdn.thewirecutter.com.

Factors to Consider when Choosing a Snowblower

Power Source

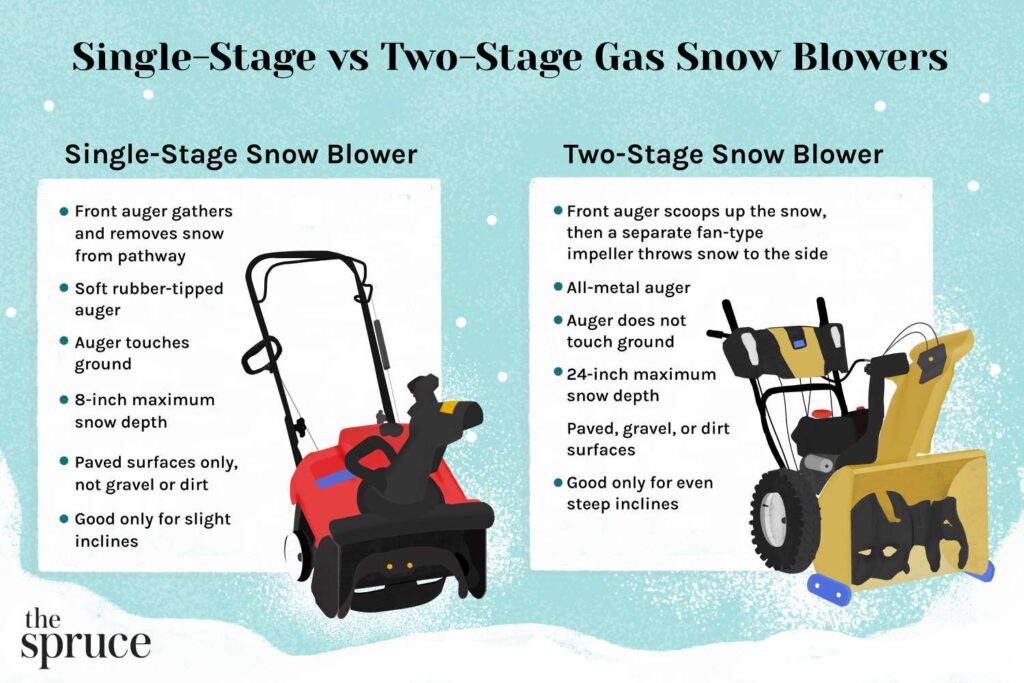

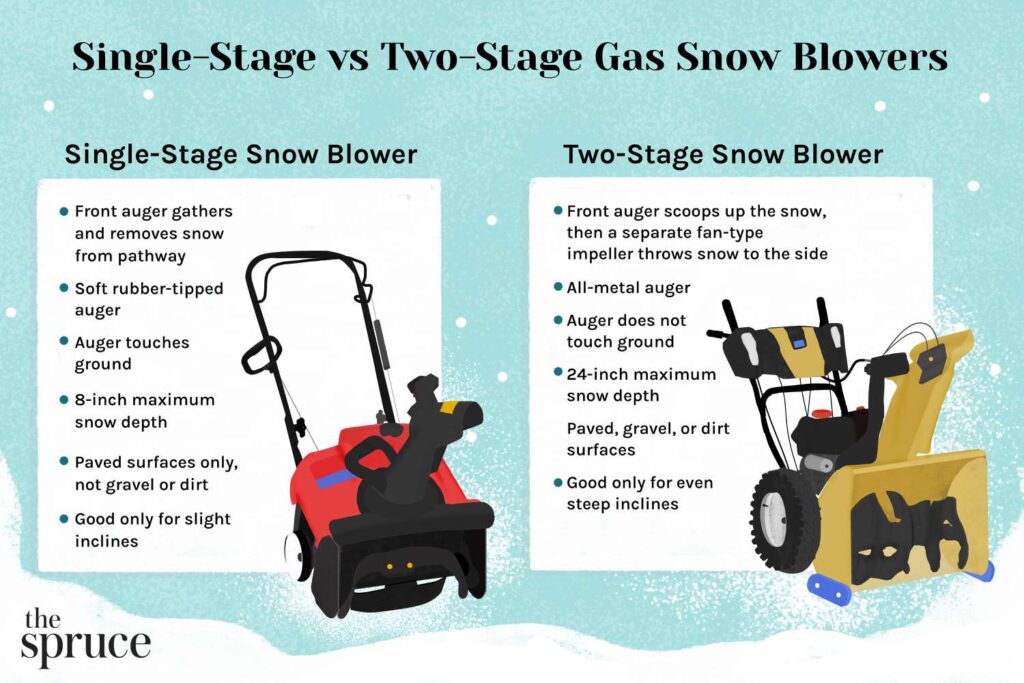

One of the first factors to consider when buying a snowblower is the power source. Snowblowers are available in three main types: gas-powered, electric, and battery-powered. Gas-powered snowblowers are known for their high power and ability to tackle large snow removal tasks. However, they require regular maintenance and can be noisy. Electric snowblowers, on the other hand, are quieter and require less maintenance, but they may not have as much power. Battery-powered snowblowers offer the convenience of cordless operation but may have limited run time.

Clearing Width

The clearing width of a snowblower refers to the width of the path it can clear in a single pass. A wider clearing width allows for faster and more efficient snow removal. However, it is important to consider the size of the area you need to clear. If you have a small driveway or walkway, a snowblower with a narrower clearing width may be more suitable.

Clearing Depth

In addition to clearing width, clearing depth is another important factor to consider. The clearing depth indicates how deep of snow the snowblower can handle. If you live in an area that experiences heavy snowfall, it is essential to choose a snowblower with a high clearing depth to ensure effective snow removal.

Throwing Distance

The throwing distance of a snowblower refers to how far it can throw the snow after clearing it. This is an important consideration especially if you need to clear a wide area or need to throw the snow away from walkways and driveways. Some snowblowers are equipped with adjustable throwing distance settings, allowing you to control where the snow is thrown.

Top Snowblower Brands in the Market

Brand A

Brand A is known for its high-quality snowblowers that are built to handle tough winter conditions. Their snowblowers are available in both gas-powered and electric models, offering customers a wide range of options. With a strong reputation for durability and reliability, Brand A products are often highly recommended by experts in the field.

Brand B

Brand B is a popular choice among homeowners who prioritize ease of use and convenience. Their electric snowblowers are lightweight and easy to maneuver, making them suitable for clearing smaller areas. Brand B also offers battery-powered snowblowers that provide the flexibility of cordless operation. While they may not have the same power as gas-powered models, Brand B products are known for their efficiency and user-friendly features.

Brand C

Brand C specializes in gas-powered snowblowers that are designed for heavy-duty snow removal. Their snowblowers are known for their high clearing width and depth, allowing for quick and efficient snow removal. With a strong focus on performance and durability, Brand C has gained a loyal customer base among those who need a reliable snowblower for large areas.

Quality and Durability

Materials Used

The quality of materials used in a snowblower can greatly affect its durability and overall performance. Snowblowers that are made with high-quality materials, such as stainless steel or heavy-duty plastic, are more likely to withstand the harsh winter conditions and last longer.

Construction Design

Apart from the materials used, the construction design of a snowblower also plays a significant role in its durability. Snowblowers with sturdy frames and reinforced components are more resistant to damage and are better equipped to handle heavy snow and ice.

Warranty

When considering the quality and durability of a snowblower, it is important to check the warranty offered by the manufacturer. A longer warranty period typically indicates that the brand has confidence in the durability and reliability of their product.

Performance and Efficiency

Engine Power

The engine power of a snowblower determines its ability to handle various snow conditions. Higher horsepower engines are better suited for heavy, wet snow and can effectively clear larger areas. However, it is important to consider the size of the area you need to clear and choose an engine power that matches your needs.

Speed Settings

The speed settings of a snowblower allow for greater control and flexibility during operation. Some snowblowers have multiple speed settings, allowing you to adjust the speed according to the snow conditions and the area you are clearing. This feature can greatly enhance performance and efficiency.

Auger Design

The design of the auger, which is responsible for collecting and throwing the snow, can greatly affect the performance of the snowblower. Snowblowers with heavy-duty augers and serrated edges are more effective in breaking up packed snow and ice, resulting in smoother and faster snow removal.

This image is property of hips.hearstapps.com.

Ease of Use and Comfort

Electric Start

An electric start feature eliminates the need for manual pulling to start the snowblower engine. This can be especially beneficial for those who may have difficulty with manual starting or for areas with frequent cold weather conditions.

Control Panel

A user-friendly and intuitive control panel can greatly enhance the ease of use of a snowblower. Clear and labeled controls make it easier to operate the snowblower and adjust settings as needed.

Handle Design

The handle design of a snowblower plays a crucial role in user comfort and maneuverability. Adjustable and ergonomic handles make it easier to control the snowblower and reduce fatigue during operation.

Noise Level

Snowblowers can be noisy, especially gas-powered models. If noise is a concern for you, it is worth considering electric or battery-powered snowblowers, which tend to be quieter during operation.

Maintenance and Support

Ease of Maintenance

Regular maintenance is essential for keeping a snowblower in optimal condition. Snowblowers that are designed with easy access to key components, such as the engine and auger, make it easier to perform routine maintenance tasks.

Availability of Replacement Parts

In the event that a part needs to be replaced, it is important to consider the availability of replacement parts. Choosing a snowblower from a reputable brand ensures that you can easily find and purchase the necessary parts if needed.

Customer Support

When investing in a snowblower, it is beneficial to consider the level of customer support provided by the manufacturer. A brand that offers reliable customer support can assist you with troubleshooting, maintenance tips, and any other concerns you may have.

This image is property of cdn.thewirecutter.com.

Price Range and Budget

Budget Considerations

Price is often an important factor to consider when making a purchase decision. Snowblowers can vary greatly in price, depending on the brand, power source, and features. It is essential to determine your budget and prioritize the features that are most important to you.

Value for Money

While it is tempting to opt for the cheapest snowblower available, it is important to consider the overall value for money. Investing in a higher-quality snowblower may result in better performance, durability, and customer satisfaction in the long run.

Reviews and Recommendations

Expert Reviews

Expert reviews and ratings can provide valuable insights into the pros and cons of different snowblower brands and models. Reading expert reviews can help you make an informed decision based on the experiences and recommendations of industry professionals.

Customer Reviews

Customer reviews offer firsthand experiences and opinions from individuals who have purchased and used a particular snowblower. Pay attention to both positive and negative reviews to get a well-rounded understanding of the product.

Word-of-Mouth Recommendations

In addition to online reviews, word-of-mouth recommendations from friends, family, and neighbors can provide valuable insights. People who live in similar climates or have similar snow removal needs can offer valuable advice on which snowblower brands and models work best for them.

This image is property of empire-s3-production.bobvila.com.

Comparison of Popular Snowblower Models

Model X

Model X is a gas-powered snowblower known for its high power and ability to handle heavy snowfall. With a wide clearing width and adjustable throwing distance, Model X is a popular choice among homeowners with large driveways and walkways.

Model Y

Model Y is an electric snowblower that offers the convenience of cordless operation. Despite its lower power compared to gas-powered models, Model Y is praised for its lightweight design and ease of use, making it ideal for clearing smaller areas.

Model Z

Model Z is a battery-powered snowblower that combines the convenience of electric operation with the flexibility of cordless use. With its adjustable speed settings and efficient auger design, Model Z is a versatile option for homeowners who need a reliable snowblower for medium-sized areas.

Conclusion

In conclusion, choosing the best brand of snowblower involves considering several factors such as power source, clearing width and depth, throwing distance, and overall performance and efficiency. It is important to prioritize quality and durability, ease of use and comfort, as well as maintenance and support. Budget considerations and reviews and recommendations from experts and other customers can also help in making an informed decision. By carefully considering all these factors, you can select the best snowblower brand and model that meets your specific needs and preferences.

This image is property of www.popsci.com.