If you’re tired of shuffling through piles of snow inch by inch, desperately hoping for a snowblower that can handle the heavy-duty work, you might be wondering if there’s a way to boost its performance. Well, the short answer is yes. You can indeed upgrade certain parts of your snowblower to enhance its overall performance and efficiency. So, let’s take a closer look at the key components that can be upgraded to tackle even the toughest winter conditions with ease. Absolutely! Upgrading certain parts of your snowblower can greatly enhance its performance and efficiency. Let’s explore some key areas where upgrades can make a significant impact.

This image is property of pixabay.com.

1. Engine Upgrades

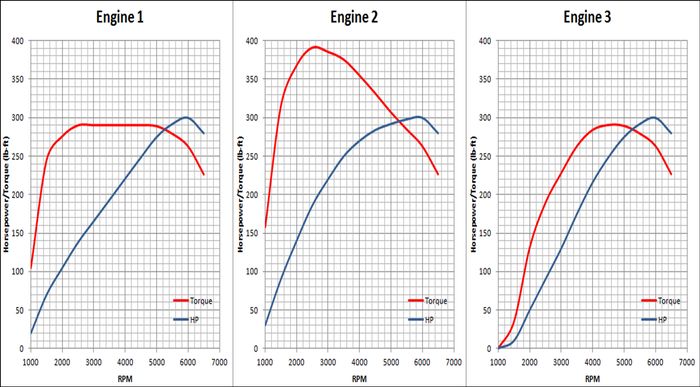

1.1 Upgrading the Horsepower

One way to boost the power and overall performance of your snowblower is by upgrading its engine horsepower. A higher horsepower engine can increase the machine’s capacity to handle heavier and deeper snow, making your job easier and more efficient. Consult with a professional or refer to your snowblower’s manual to determine the compatible engine horsepower upgrade options for your specific model.

1.2 Installing a High-Performance Air Filter

Another engine upgrade that can improve the performance of your snowblower is installing a high-performance air filter. A quality air filter can enhance the airflow to the engine, allowing for better combustion and increased power output. By preventing dirt and debris from entering the engine, a high-performance air filter also helps prolong the engine’s lifespan.

1.3 Upgrading the Spark Plug

Upgrading to a high-quality spark plug is a simple yet effective way to optimize the performance of your snowblower’s engine. A spark plug with efficient combustion capabilities ensures a smooth and consistent ignition process, leading to improved fuel efficiency and enhanced overall performance. It’s recommended to choose a spark plug specifically designed for snowblower engines to ensure compatibility and optimal results.

1.4 Using a Performance Fuel Additive

Incorporating a performance fuel additive into your snowblower’s fuel system can provide several benefits. These additives are formulated to clean and optimize the fuel system, improving fuel efficiency and maintaining engine performance. Additionally, performance fuel additives can prevent fuel system corrosion, which can extend the lifespan of your snowblower’s engine.

2. Transmission Upgrades

2.1 Upgrading to an Automatic Transmission

If your snowblower currently operates with a manual transmission, upgrading to an automatic transmission can greatly simplify the operation and increase overall efficiency. An automatic transmission allows for seamless gear shifting, eliminating the need for manual intervention. This upgrade is particularly beneficial if you have a large area to clear or if you struggle with physical exertion.

2.2 Installing Synthetic Transmission Fluid

Enhancing the performance of your snowblower’s transmission can be achieved by switching to synthetic transmission fluid. Synthetic fluids offer improved lubrication properties, better heat resistance, and enhanced overall performance compared to conventional transmission fluids. They also contribute to smoother gear shifts and reduced wear and tear on the transmission components, leading to a longer lifespan for your snowblower.

This image is property of pixabay.com.

3. Auger Upgrades

3.1 Upgrading the Auger Blades

The auger blades are essential for effectively cutting and moving snow in your snowblower. Upgrading to high-quality, durable auger blades can significantly improve the performance of your machine. These blades are designed to handle heavy snow accumulation and maintain their sharpness for extended periods, reducing the effort required to clear snow and ensuring a more consistent and efficient operation.

3.2 Installing a Heavy-Duty Auger Belt

The auger belt is responsible for transferring power from the engine to the auger blades. Upgrading to a heavy-duty auger belt can enhance the overall durability and performance of your snowblower. These belts are specifically designed to handle the increased power demands of upgraded engines or harsh operating conditions, minimizing the risk of belt slippage and improving snowblowing efficiency.

4. Chute and Impeller Upgrades

4.1 Upgrading the Chute Control System

The chute control system determines the direction and angle at which the snow is expelled from the snowblower. Upgrading to a more advanced and precise chute control system allows for better control over the snow discharge, increasing the efficiency and accuracy of the snowblowing process. Look for features such as one-touch rotation control and enhanced vertical adjustment to optimize your snowblowing experience.

4.2 Installing a Higher Capacity Impeller

The impeller plays a crucial role in propelling the snow out of the chute. Upgrading to a higher capacity impeller can significantly increase the snowblower’s throwing distance and overall performance, making it more effective in clearing deep or densely packed snow. Consider consulting a professional to determine the compatible impeller upgrade options for your specific snowblower model.

This image is property of pixabay.com.

5. Handle and Controls Upgrades

5.1 Upgrading to Electric Start

Struggling with a manual pull-start system on your snowblower? Upgrading to an electric start system can save you the hassle and physical exertion. With a simple push of a button, you can effortlessly start your snowblower, even in cold weather conditions. Electric start systems are reliable and time-saving, allowing you to focus on clearing snow rather than wrestling with a stubborn pull-start mechanism.

5.2 Installing Heated Handle Grips

Snowblowing in freezing temperatures can take a toll on your hands. Upgrading to snowblower handle grips with built-in heating elements can keep your hands warm and comfortable during prolonged snowblowing sessions. These heated grips provide a cozy and ergonomic grip, reducing fatigue and enhancing your overall snowblowing experience.

6. Tires and Tracks Upgrades

6.1 Upgrading to Snow Tires

If your snowblower uses standard tires, upgrading to snow tires designed specifically for winter conditions can vastly improve its traction and maneuverability. Snow tires have deeper tread patterns, allowing them to grip slippery surfaces more effectively. This upgrade is particularly beneficial if you frequently encounter icy or packed snow surfaces where standard tires may struggle to provide sufficient traction.

6.2 Installing Tracks for Better Traction

For even greater traction in challenging snow conditions, consider installing tracks on your snowblower. Tracks provide superior grip and stability on uneven terrains, allowing you to effortlessly navigate through deep snow, slopes, or icy surfaces. This upgrade is especially valuable if you have a large area to clear or if your property is on uneven terrain.

7. Lighting Upgrades

7.1 Upgrading the Headlights

Snowstorms often bring reduced visibility, making it difficult to navigate your snowblower safely. Upgrading the headlights to brighter, more powerful ones can greatly improve visibility in low light conditions. Choose headlights with a wide beam pattern and adjustable angles to ensure optimal illumination of your working area, keeping you safe and allowing for efficient snow clearing, even during nighttime or early morning hours.

7.2 Installing LED Lights for Better Visibility

In addition to upgrading the headlights, installing LED lights on your snowblower can further enhance visibility and safety. LED lights offer superior brightness, energy efficiency, and longer lifespan compared to traditional incandescent bulbs. With LED lights, you can have clear visibility of both your snowblower’s immediate surroundings and potential obstacles in your path, allowing for a more precise and efficient snow-clearing experience.

8. Belt and Pulley Upgrades

8.1 Installing a Heavy-Duty Belt

The belt-driven components of your snowblower, such as the auger and drive system, are key to its overall performance. Upgrading to a heavy-duty belt can ensure efficient power transfer and prevent slippage, even under extreme operating conditions. Heavy-duty belts are designed to withstand rigorous use, providing enhanced reliability and durability, particularly when paired with upgraded engines or high-performance modifications.

8.2 Upgrading to a Larger Pulley System

Upgrading the pulley system in your snowblower can have a significant impact on its overall performance and efficiency. Installing larger pulleys can increase the speed and power output, resulting in improved snowblowing capabilities. However, it’s essential to consult a professional or refer to your snowblower’s manual to ensure compatibility and safe operation when considering a pulley system upgrade.

9. Blower Housing and Impeller Upgrades

9.1 Upgrading to a Larger Blower Housing

If you frequently deal with heavy or wet snow, upgrading to a larger blower housing can enhance the snowblower’s capacity to intake and clear large volumes of snow effectively. A larger blower housing allows for higher snowblowing rates and greater efficiency, reducing the need for multiple passes to clear a given area. It’s important to ensure that the upgraded blower housing is compatible with your snowblower model and properly installed for optimal performance.

9.2 Installing a High-Efficiency Impeller

The impeller is responsible for drawing in snow and propelling it out of the chute. Installing a high-efficiency impeller can significantly increase the snowblower’s throwing distance and overall performance. High-efficiency impellers are designed to maximize the snowblower’s ability to clear dense or heavy snow quickly and efficiently. Consult with a professional or refer to your snowblower’s manual to determine suitable impeller upgrade options for your specific model.

10. Maintenance and Care for Better Performance

10.1 Regular Cleaning and Lubrication

To ensure optimal performance and longevity of your snowblower, regular cleaning and lubrication are essential. Clean out debris and snow accumulation after each use, paying particular attention to the chute, auger blades, and other moving parts. Applying lubricant to key components, such as the auger shaft and impeller, reduces friction and enhances performance. Follow the manufacturer’s guidelines for proper cleaning and lubrication procedures.

10.2 Proper Storage and Winterization

When the snowblowing season comes to an end, it’s crucial to properly store and winterize your machine. Clean the snowblower thoroughly, removing any residual snow and debris. Drain the fuel tank or add a fuel stabilizer to prevent fuel degradation during storage. Disconnect or remove the spark plug to protect against accidental starts. Store the snowblower in a dry and secure location, following the manufacturer’s instructions for proper storage procedures.

In conclusion, upgrading various parts of your snowblower can significantly enhance its performance, efficiency, and overall snow-clearing capabilities. From engine upgrades and transmission enhancements to auger and impeller improvements, there are numerous options available to optimize your snowblower for the most challenging winter conditions. Remember to consult professionals or refer to the manufacturer’s guidelines when considering any upgrades or modifications to ensure compatibility and safe operation. With the right upgrades and regular maintenance, you can take your snowblower to the next level, making snow removal a breeze.