So you’re in the market for a new snowblower, but you’re not quite sure what type of transmission to go for – manual or automatic? Well, fear not, because we’re here to break it down for you. When it comes to manual snowblower transmissions, the power is in your hands – literally. With manual transmissions, you have total control over the speed and direction of your machine, making it a great choice for those who prefer a hands-on approach. On the other hand, automatic snowblower transmissions offer convenience and simplicity. Just set your desired speed, and the machine takes care of the rest. It’s a tough decision to make, but we’ll help you weigh the pros and cons of each so you can make an informed choice.

Transmission Types

When it comes to snowblowers, one of the key factors to consider is the type of transmission it has. The two main types of transmissions found in snowblowers are manual and automatic. Each type has its own benefits and considerations, and understanding the differences can help you make an informed decision when purchasing a snowblower.

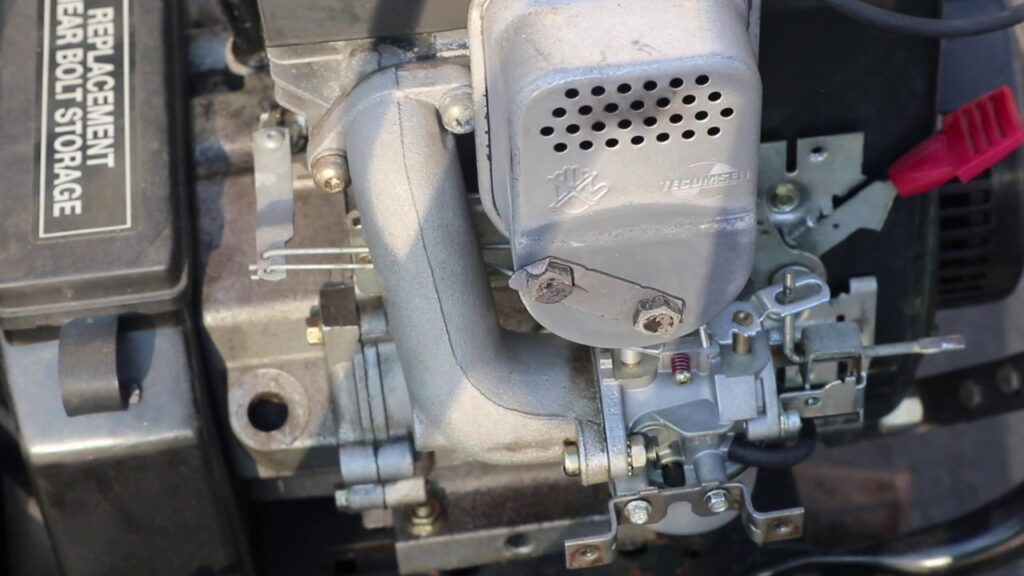

Manual Transmission

A manual transmission in a snowblower operates similarly to a manual transmission in a car. With a manual transmission snowblower, you have control over the gear selection and shifting. This means that you manually shift gears to adjust the speed and power of the snowblower. Manual transmissions often have multiple forward gears and a reverse gear, giving you a range of options to suit different snow conditions.

Automatic Transmission

On the other hand, an automatic transmission in a snowblower takes care of the shifting for you. The transmission automatically adjusts the gear ratios and shifting based on the speed and load of the snowblower. This can make operation more convenient and user-friendly, especially for those who may not be comfortable or familiar with shifting gears manually.

Control and Operation

When it comes to control and operation, the type of transmission in a snowblower can have a significant impact. Let’s take a closer look at some key aspects of control and operation with both manual and automatic transmissions.

Engagement

Engaging the transmission is an important step in operating a snowblower. With a manual transmission, you typically engage the clutch and select the appropriate gear before starting to clear snow. This can require some coordination and practice to ensure smooth engagement.

On the other hand, with an automatic transmission, the engagement process is simplified. You simply start the snowblower and it automatically engages the transmission, allowing you to focus on clearing snow without having to worry about clutch operation.

Shifting

Shifting gears is a crucial aspect of controlling the speed and power of a snowblower. In a manual transmission snowblower, you have the flexibility to manually shift gears based on the conditions and the amount of snow you need to clear. This allows for greater control and customization of the snowblowing process.

With an automatic transmission, shifting gears is taken care of by the snowblower itself. The transmission automatically adjusts the gear ratios and shifting based on the load and speed of the snowblower. This can be a convenient feature, especially for those who may not be comfortable or experienced with manual shifting.

Speed Control

Controlling the speed of a snowblower is essential for efficient and effective snow clearing. With a manual transmission, you have direct control over the speed by selecting the appropriate gear. This gives you the ability to increase or decrease the speed as needed, allowing for better control and adaptability to different snow conditions.

On the other hand, with an automatic transmission, the snowblower adjusts the speed based on the load and speed setting. This can be convenient for those who prefer a more automated approach to snow removal, as the snowblower automatically adjusts the speed for optimal performance.

Efficiency

Efficiency is an important consideration when it comes to snowblowers, as it can impact both performance and fuel consumption. Let’s explore how manual and automatic transmissions affect efficiency in snowblowers.

Power Transfer

In terms of power transfer, manual transmissions generally provide a more direct connection between the engine and the wheels. This can result in more efficient power transfer, allowing for greater control and performance, especially in heavy and deep snow.

Automatic transmissions, on the other hand, may introduce some loss of power due to the torque converter. However, modern automatic transmissions have significantly improved efficiency and can provide smooth and consistent power transfer.

Fuel Consumption

Fuel consumption is another important aspect to consider, as it directly affects operating costs and environmental impact. Manual transmissions in snowblowers generally require more frequent shifting and may require the operator to keep the engine at a higher RPM to maintain power. This can result in increased fuel consumption compared to automatic transmissions.

Automatic transmissions, on the other hand, can optimize the gear ratios and shifting to provide better fuel efficiency. The transmission adjusts the gear ratios based on the load and speed, allowing for more efficient use of fuel and potentially reducing overall fuel consumption.

Maintenance

Maintenance is an important aspect of owning any machinery, and snowblowers are no exception. Let’s explore some key considerations for maintenance with both manual and automatic transmissions.

Maintenance Needs

In terms of maintenance needs, manual transmissions generally require more attention and maintenance compared to automatic transmissions. This is mainly due to the increased complexity and moving parts involved in manual shifting.

With a manual transmission, regular lubrication and adjustment of the clutch and gears are necessary to ensure smooth operation. Additionally, periodic checks and adjustments of the clutch and shifting linkage may be required.

On the other hand, automatic transmissions in snowblowers are generally more maintenance-free. The transmission is designed to provide reliable and consistent performance without the need for frequent adjustments or lubrication.

Durability

Durability is a key factor to consider when investing in a snowblower. Both manual and automatic transmissions can be durable, but certain factors may affect their longevity.

Manual transmissions typically have fewer moving parts, which can make them more robust and less prone to failure. However, improper shifting or excessive use of force can lead to premature wear and damage.

Automatic transmissions, on the other hand, may be more complex and have more components. While modern automatic transmissions are designed to be durable, improper operation or lack of maintenance can lead to premature wear and potential transmission issues.

User Experience

User experience plays a significant role in overall satisfaction and ease of use when operating a snowblower. Let’s explore how manual and automatic transmissions contribute to the user experience.

Ease of Use

When it comes to ease of use, automatic transmissions offer a clear advantage. Automatic transmissions eliminate the need for manual shifting, making the operation more straightforward and user-friendly, especially for those less familiar with operating machinery.

Manual transmissions, on the other hand, require more coordination and skill to operate smoothly. Shifting gears at the right time and maintaining control of the snowblower can take practice and may be challenging for some users.

Comfort

Comfort is another important aspect of the user experience when operating a snowblower. Automatic transmissions generally provide a smoother and more comfortable ride, as they optimize shifting for optimal engine performance and reduced vibrations.

Manual transmissions may require more frequent shifting, which can result in a less smooth and comfortable experience. The need to coordinate shifting and clutch operation can also cause more fatigue during extended use.

Fatigue

Snowblowing can be a physically demanding task, and minimizing fatigue is crucial for efficient and safe operation. Automatic transmissions can help reduce fatigue by eliminating the need for frequent shifting and allowing the operator to focus more on clearing snow.

Manual transmissions may require more physical effort and coordination, leading to increased fatigue during operation. The need to shift gears and control the clutch can be tiring, especially when dealing with heavy or deep snow.

Cost

Cost is a significant consideration for many buyers when it comes to purchasing a snowblower. Let’s break down the cost aspects related to manual and automatic transmissions.

Initial Cost

In terms of initial cost, manual transmission snowblowers tend to be more affordable compared to their automatic counterparts. The simpler design and fewer components in manual transmissions contribute to a lower overall cost.

Automatic transmission snowblowers often come with a higher price tag due to the added complexity and technology involved in the transmission system. However, it’s essential to consider other factors such as the intended use and long-term benefits when evaluating the initial cost.

Maintenance Cost

When it comes to maintenance cost, manual transmission snowblowers generally have lower maintenance requirements, resulting in potentially lower costs. Manual transmissions have fewer components and often require less frequent maintenance or repairs.

Automatic transmission snowblowers may require more periodic maintenance and potentially cost more to repair or service due to the complexity of the transmission system. However, modern automatic transmissions are designed to be reliable and may not require significant maintenance throughout their lifespan.

Versatility

Versatility is an important factor to consider, especially if you need a snowblower that can handle various terrain conditions or accommodate attachments for additional functionality. Let’s explore how transmission types affect the versatility of snowblowers.

Terrain Adaptability

In terms of terrain adaptability, manual transmission snowblowers offer more flexibility. The ability to manually shift gears allows for greater control and adaptability to different terrain conditions, such as inclines or uneven surfaces. This can be particularly useful if you have a hilly or challenging landscape to clear.

Automatic transmission snowblowers may provide limited gear options, which can impact their performance on different terrains. However, modern automatic transmissions are designed to provide optimal performance in various conditions, and many models offer features such as traction control to enhance adaptability.

Attachments

Attachments can expand the functionality of your snowblower and allow you to tackle a broader range of tasks. Manual transmission snowblowers are often compatible with various attachments, such as snow thrower or brush attachments, which can be advantageous if you need to use the snowblower for other purposes beyond snow clearing.

Automatic transmission snowblowers may also offer compatibility with attachments, although the availability and range of options may vary depending on the specific model and manufacturer. It’s essential to check the compatibility and availability of attachments when considering an automatic transmission snowblower.

Durability

Durability is a crucial aspect when investing in a snowblower, as you want a machine that can withstand the rigors of snow clearing. Let’s explore how transmission types can affect the overall durability of snowblowers.

Components

Manual transmissions in snowblowers generally have fewer components compared to automatic transmissions. This simpler design can contribute to improved durability, as there are fewer moving parts that can potentially malfunction or wear out over time.

Automatic transmissions may have slightly more components and complexity, which can introduce a higher risk of potential failure or wear. However, modern automatic transmissions are engineered to be durable and reliable under normal operating conditions.

Wear and Tear

The amount of wear and tear a snowblower transmission experiences can impact its overall durability. Manual transmissions may experience less wear and tear since the operator has more control over the shifting and can avoid excessive strain on the transmission components.

Automatic transmissions may experience slightly more wear and tear due to the automated shifting and adjustment of gear ratios. However, regular maintenance and proper operation can help minimize wear and extend the lifespan of the transmission.

Availability

Availability is an important consideration when purchasing a snowblower, as you want to have access to a range of options and potential accessories. Let’s explore how transmission types affect availability in the snowblower market.

Market Options

Manual transmission snowblowers tend to have a wider range of options available on the market. Due to their simplicity and popularity, manual transmission snowblowers are commonly offered by various brands and in different sizes and power capacities. This provides buyers with more flexibility in finding a snowblower that suits their needs.

Automatic transmission snowblowers, while increasingly popular, may still have a more limited market availability compared to manual transmissions. However, as the demand for automatic snowblowers continues to grow, manufacturers are expanding their offerings to meet customer needs.

Accessories

The availability of accessories can enhance the functionality and versatility of your snowblower. Manual transmission snowblowers often have a wider range of readily available attachments and accessories on the market. These can include snow throwers, brushes, or even plows, allowing you to customize your snowblower to suit your specific needs.

Automatic transmission snowblowers, while still offering attachment compatibility, may have a more limited range of accessories available. However, manufacturers are increasingly developing attachments specifically designed for automatic snowblowers, providing users with more options and versatility.

Conclusion

Choosing between a manual and automatic transmission snowblower ultimately comes down to personal preference, specific needs, and budget. Both transmission types have their own advantages and considerations. Manual transmissions offer greater control, flexibility, and affordability, while automatic transmissions provide convenience, ease of use, and potentially improved fuel efficiency.

Consider factors such as the terrain you need to clear, the level of user expertise and comfort, and the long-term maintenance and operating costs. By evaluating these aspects and understanding the differences between manual and automatic transmission snowblowers, you can make an informed decision that suits your specific snow clearing needs.