So you’ve got a snowblower and you’ve recently started noticing that it’s not performing as well as it used to. Well, one potential culprit could be a clogged or outdated air filter. A snowblower’s air filter is a crucial component in ensuring optimal performance and preventing debris from entering the engine. In this article, we will explore the steps you can take to upgrade your snowblower’s air filter, allowing it to breathe easier and tackle those winter woes with renewed efficiency.

Why upgrade your snowblower’s air filter?

When it comes to maintaining your snowblower, upgrading your air filter is an often overlooked but important task. The air filter plays a crucial role in protecting your snowblower’s engine from harmful debris and ensuring optimal performance. Upgrading your air filter can improve engine performance, extend its life, and even save you money on fuel and maintenance costs. In this article, we will discuss the different types of air filters, signs that your air filter needs upgrading, how to choose the right air filter upgrade, and tips for maintaining and maximizing its performance.

Types of air filters

There are several types of air filters available for snowblowers, each with their own advantages and considerations. Here are some of the most common types:

Foam air filters

Foam air filters are made of a fine, porous material that effectively captures dirt and debris from entering the engine. They are known for their excellent filtration capabilities, especially for finer particles. Foam air filters are often washable and reusable, making them a cost-effective option in the long run. However, it’s important to avoid over-oiling foam filters, as excess oil can restrict airflow and lead to reduced engine performance.

Paper air filters

Paper air filters are made of a pleated paper material that effectively traps larger particles and debris from entering the engine. They offer good filtration efficiency and are often replaceable, ensuring convenient maintenance. Paper air filters are generally easy to install and provide reliable protection for your snowblower’s engine.

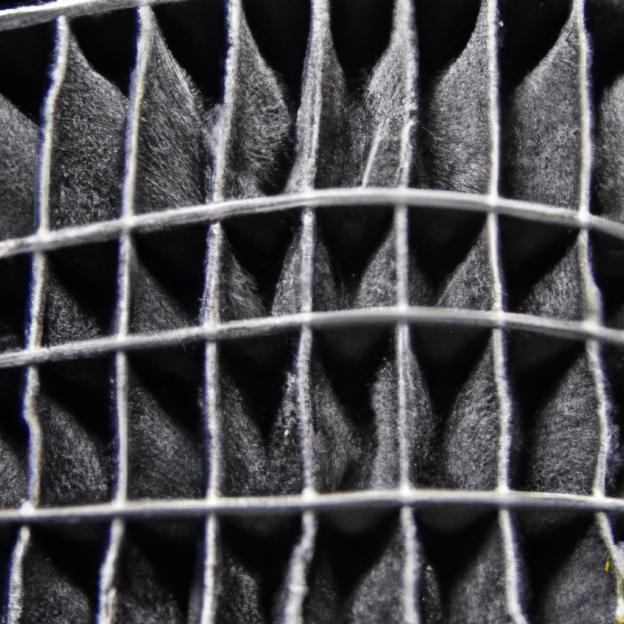

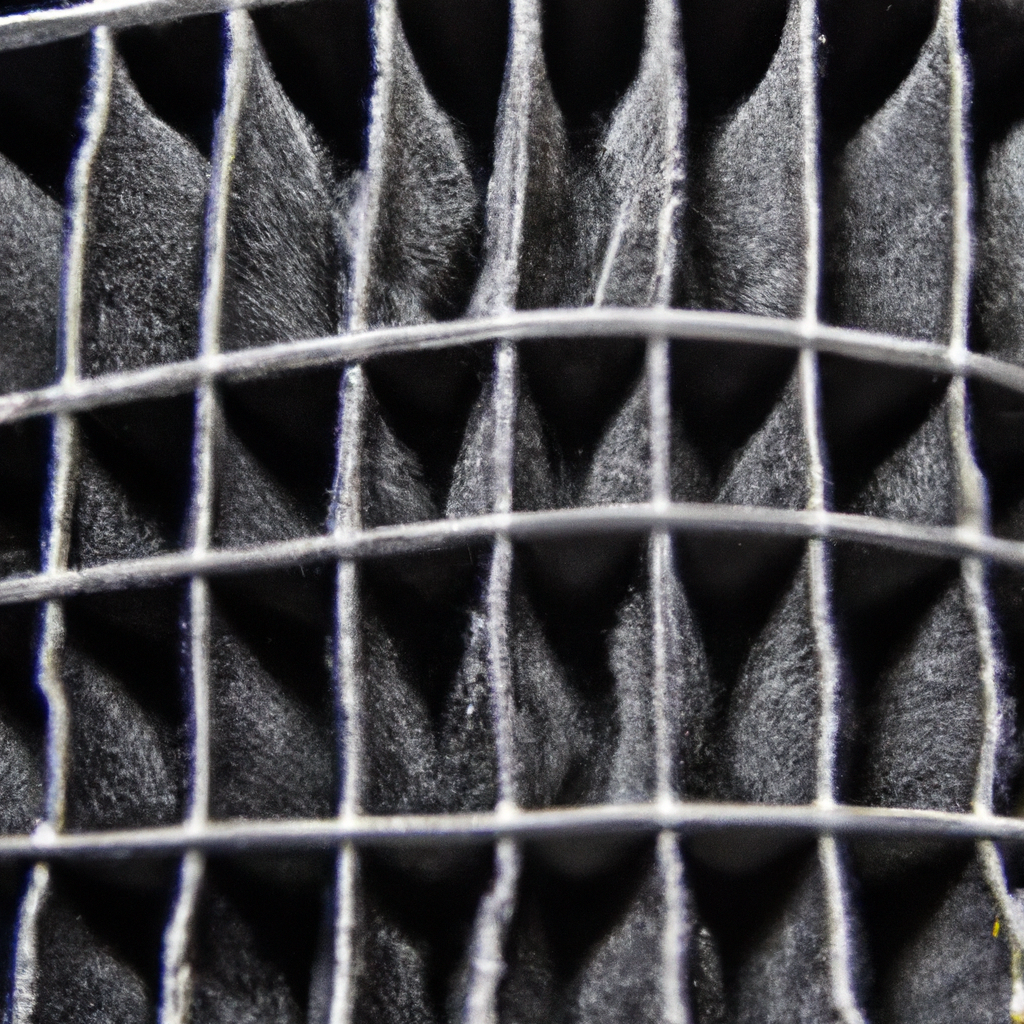

Mesh air filters

Mesh air filters, also known as wire mesh filters, are made of a fine metal mesh material that filters out larger particles while allowing sufficient airflow. They are durable and can withstand heavy use and harsh outdoor conditions. Mesh air filters are often washable and reusable, making them a cost-effective option in the long run. However, they may not provide the same level of filtration efficiency as foam or paper filters.

Cotton air filters

Cotton air filters, also known as gauze filters, are constructed with layers of cotton fabric and an oil coating that captures and holds particles. They offer excellent filtration efficiency and can improve engine performance by allowing better airflow. Cotton air filters are often washable and reusable, making them environmentally friendly and cost-effective. However, they require regular maintenance and careful oiling to ensure optimal performance.

Signs that your air filter needs upgrading

Understanding when to upgrade your snowblower’s air filter is essential for maintaining its performance and protecting the engine. Here are some common signs that indicate your air filter may need an upgrade:

Restricted airflow

If you notice a decrease in the airflow coming from your snowblower’s engine, it may be a sign that the air filter is clogged or worn out. Restricted airflow can significantly impact engine performance and efficiency, making it important to upgrade your air filter promptly.

Reduced engine performance

A snowblower that is struggling to start, experiencing power fluctuations, or producing unusual noises may be a result of a dirty or inadequate air filter. When the air filter becomes clogged, it can restrict the amount of air entering the engine, leading to reduced performance and potential damage in the long run. Upgrading your air filter can help restore your snowblower’s engine to its optimal performance.

Excessive fuel consumption

If you find that your snowblower is consuming more fuel than usual, it could be a sign that the air filter is not effectively filtering out dirt and debris. A clogged or inefficient air filter can cause the engine to work harder, resulting in increased fuel consumption. Upgrading to a more efficient air filter can improve fuel efficiency and save you money in the long term.

Choosing the right air filter upgrade

When it comes to choosing the right air filter upgrade for your snowblower, there are a few factors to consider. These factors will help ensure compatibility, filtration efficiency, and ease of maintenance. Here are some key considerations:

Consider your snowblower model

Different snowblower models may require specific air filter types or sizes. It’s important to consult your snowblower’s manual or manufacturer to determine the recommended air filter specifications. By choosing the right air filter that is designed for your specific snowblower model, you can ensure optimal performance and compatibility.

Evaluate filtration efficiency

Filtration efficiency refers to how well the air filter captures and retains dirt and debris. A higher filtration efficiency ensures better protection for your snowblower’s engine. Consider the type of debris commonly encountered in your snowblowing environment and choose an air filter that can effectively filter those particles. Foam and paper filters generally offer higher filtration efficiency, while mesh and cotton filters may have slightly lower efficiency but still provide adequate protection.

Check maintenance requirements

Different air filters have varying maintenance requirements. Some filters are washable and reusable, while others require replacement after a certain period. Consider your preference and convenience when it comes to maintenance tasks. Keep in mind that proper maintenance is crucial for optimal air filter performance, so choose a filter that aligns with your ability and commitment to regular maintenance.

How to upgrade your snowblower’s air filter

Now that you have chosen the right air filter upgrade for your snowblower, here are the steps to properly upgrade the air filter:

Research compatibility options

Before making a purchase, ensure that the new air filter is compatible with your snowblower model. Refer to your snowblower’s manual or consult the manufacturer to determine the correct filter size and type. Research reputable brands and read customer reviews to ensure the filter’s reliability and performance.

Remove the old air filter

To remove the old air filter, consult your snowblower’s manual for specific instructions. In general, you may need to open the air filter housing or remove a cover to access the filter. Carefully remove the old filter, taking note of its orientation and any clips or fasteners that may be holding it in place.

Install the new air filter

Take the new air filter and ensure it matches the specifications and orientation of the old filter. Insert the new filter into the air filter housing, paying attention to any notches or alignment guides. Press the filter firmly against the housing to ensure a proper seal.

Secure the air filter housing

Once the new filter is properly installed, close the air filter housing or replace the cover according to your snowblower’s instructions. Make sure any clips or fasteners are securely tightened to prevent any air leaks.

Maintaining your upgraded air filter

After upgrading your snowblower’s air filter, proper maintenance is crucial for ensuring its long-term performance. Here are some tips for maintaining your upgraded air filter:

Regular cleaning

If your air filter is washable and reusable, it’s important to clean it regularly. Follow the manufacturer’s instructions for cleaning, which may involve using a mild detergent or a specific cleaning solution. Gently rinse the filter with water and allow it to fully dry before reinstallation. Regular cleaning helps remove accumulated debris and keeps the filter functioning at its best.

Replacement intervals

For air filters that require replacement, it’s important to follow the manufacturer’s recommended replacement intervals. Over time, even the most efficient air filters will become less effective due to clogging and wear. Regularly inspect the condition of the filter and replace it when necessary to maintain optimal engine performance and protection.

Storing your snowblower for the offseason

When storing your snowblower for the offseason, it’s important to properly prepare and protect not only the machine but also the air filter. Clean the air filter thoroughly and ensure it is completely dry before storing. Consider covering the air filter housing with a breathable material to prevent dust and debris from entering during storage.

Additional tips for maximizing air filter performance

To further maximize the performance of your snowblower’s air filter, consider the following tips:

Avoid over-oiling foam filters

If you are using a foam air filter, be cautious not to over-oil it. Excess oil can restrict airflow and negatively impact engine performance. Follow the manufacturer’s instructions for oiling the filter, ensuring a thin and even coating.

Inspect for cracks or tears

Regularly inspect your air filter for any signs of damage such as cracks or tears. Damaged filters can allow debris to bypass the filtration system and enter the engine, causing potential damage. If you notice any damage, promptly replace the air filter to maintain optimal protection.

Protect the air filter from moisture

Excess moisture can damage the air filter and reduce its effectiveness. When operating your snowblower in wet or snowy conditions, take measures to protect the air filter from direct exposure to moisture. Consider using a rain cover or a shield to prevent water from directly contacting the filter.

Avoid operating your snowblower in dusty conditions

Dust and fine particles can quickly accumulate in the air filter, clogging it and reducing performance. Whenever possible, avoid operating your snowblower in excessively dusty conditions. If unavoidable, consider upgrading to an air filter with higher filtration efficiency or clean the filter more frequently.

Benefits of upgrading your snowblower’s air filter

Upgrading your snowblower’s air filter offers a range of benefits that are worth considering. Here are some advantages of upgrading:

Improved engine performance

A clean and efficient air filter allows for better airflow, resulting in improved engine performance. Upgrading to an air filter with higher filtration efficiency can prevent dirt and debris from reaching the engine, reducing power loss and improving overall performance.

Extended engine life

By upgrading your air filter, you can protect your snowblower’s engine from harmful contaminants. Clean air is essential for engine longevity, as it reduces wear and tear on internal components. An upgraded air filter can help extend the life of your snowblower’s engine, saving you money on costly repairs or replacements.

Cost savings on fuel and maintenance

Upgrading to a more efficient air filter can improve fuel efficiency by minimizing engine strain and reducing fuel consumption. In addition, properly maintaining and replacing the air filter at regular intervals can prevent engine damage and expensive repairs. By investing in a quality air filter, you can potentially save money on fuel and maintenance costs in the long run.

Conclusion

Upgrading your snowblower’s air filter is a simple yet effective way to improve engine performance, prolong engine life, and save money on fuel and maintenance. Consider the different types of air filters available, signs that indicate an air filter upgrade is needed, and factors to consider when choosing the right air filter. Follow the proper steps to upgrade and maintain your air filter, and maximize its performance by avoiding over-oiling foam filters, inspecting for damage, protecting the filter from moisture, and avoiding dusty conditions. Upgrade your air filter today and experience the benefits it can bring to your snowblower. Stay proactive in maintaining your snowblower’s air filter, and your snowblower will reward you with reliable and efficient performance for many winters to come.